Hello TK saha, it is locate to possess bracketing or matrix approach for re-validation of media fills on semi annually foundation, nevertheless it truly is mandate to perform media fill for all pack sizes when you are introducing a fresh pack into the road.

Validation of element processing ought to boost a approach stimulation test using nutrient medium known as media fill. A media fill is 1 part of the validation of an aseptic manufacturing procedure. The goal of a media fill will be to test whether or not the aseptic technique is satisfactory to forestall microbiological contamination during the particular approach.

Visitors in the region with the DCCA is minimized and managed. The DCCA is shielded from all much less clean air currents which can be of greater velocity as opposed to clean laminar airflow.

The content material of our website is usually readily available in English and partly in other languages. Choose your most popular language and We're going to teach you the content in that language, if out there.

Compounding supervisors shall make sure by means of both direct measurement or acceptable information and facts resources that precise CSPs preserve their labeled power inside monograph limitations for USP articles or blog posts, or within ten% if not specified, until their further than-use dates.

The media picked need to be revealed to promote the growth of gram-constructive and gram-damaging micro organism, and yeast and mould. The evaluation media ought to go a growth promotion test. Management organisms should consist of appropriate strains of test microorganisms determined as suitable for use in The expansion promotion test by suitable pharmacopoeias.

All rubber stoppers of vials and bottles along with the neck of ampuls are sanitized with IPA before the introduction of a needle or spike with the elimination of products.

Training and TRAINING The assurance of CSP good quality and packaging integrity is very dependent on the proper adherence of all personnel into the pertinent composed techniques. The pharmacy ought to design, employ, and retain a proper education and learning, training, and competency evaluation software that encompasses many of the capabilities and tasks resolved from the foregoing sections and all staff to whom this kind of capabilities and duties are assigned.

Provides necessary frequently or if not needed close at hand although not necessarily needed with the scheduled operations with the shift are decontaminated and stored over the shelving from the anteroom region.

Only limited material is obtainable in the selected language. All written content is obtainable on the worldwide internet site. Close

The vital requirements which might be special to CSPs and which can be important to assure product good quality and packaging integrity has to be resolved in published strategies. For instance, procedures should be specified to prevent the despair of syringe plungers or dislodging of syringe suggestions through managing and transportation. In addition, disconnection of process components (one example is, where by CSPs are dispensed with administration sets hooked check here up to them) should be prevented through the daily life cycle with the products.

one. Following the incubation period of the media-filled containers, they are visually examined for microbial development. Contaminated containers need to be examined for proof of container/closure harm which could compromise the integrity in the packaging method. Ruined containers shouldn't be bundled as failures (positives) when evaluating final results.

For top-possibility operations, it is especially vital to reduce the potential risk of contamination on lab coats, coveralls, and various garb to generally be worn during the buffer or cleanse space. Ideally, new clear garb needs to be donned upon Each website individual entry in the buffer or clear region to prevent liberating contaminants from previously worn garb.

Media preparation data Assessment to guarantee that media was adequately formulated, dissolved and filtered.

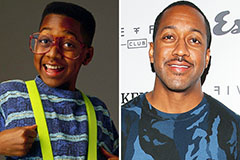

Jaleel White Then & Now!

Jaleel White Then & Now! Karyn Parsons Then & Now!

Karyn Parsons Then & Now! Traci Lords Then & Now!

Traci Lords Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!